Opis

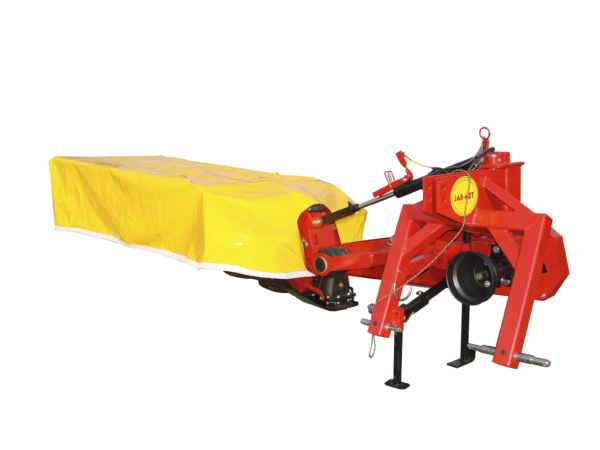

Suspended orchard sprayer is a modern implement used for performing precise applications of plant protection in orchards and strawberry plantations. The construction of the sprayer enables its easy operation and ensures proper control of operation during performed applications. Significant capacity of the tank and high efficiency of the fan allows for operation of sprayers in various plantations, even in permanent orchards where a large spraying dose is required per surface unit. Fan, precise nozzles, control valve and additional equipment of the machine applied in the sprayer guarantee good quality of performed applications at optimal usage of plant protection products.

Sprayers can be equipped with a traditional attachment (low – standard equipment) or column (high – optional equipment). The fan of the attachment receives drive from the pump shaft through the belt transmission which allows for turning on and off the fan drive.

Technical specification of mounted orchard sprayers

| Lp. |

Specyfication |

Unit of measure |

Data |

||||||||

|

300 l |

400 l |

600 l |

800 l |

1000 l |

|||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

||||

| 1. | Machine symbol |

– |

P226 |

P226/1 |

P226/2 |

P226/3 |

P226/4 |

||||

| 2. | Overall dimensions– length

– width – height |

mm mm mm |

1420 1130 1230 |

1420 1130 1360 |

1490 1400 1540 |

1490 1545 1540 |

1490 1545 1755 |

||||

| 3. | Sprayer weight |

kg |

155 |

160 |

210 |

215 |

230 |

||||

| Permissible total weight |

kg |

470 |

575 |

825 |

1030 |

1245 |

|||||

| 4. | Pump | ||||||||||

| Manufacturer |

– |

UDOR |

|||||||||

| Type |

– |

KAPPA 65 |

|||||||||

| Outflow intensity at:- 0.0 MPa (540 rpm)

– max MPa (540 rpm) |

rpm |

66,3 |

|||||||||

|

rpm |

63,6 |

||||||||||

| Max working pressure |

bar |

40 |

|||||||||

| Working rotations |

rpm |

540 |

|||||||||

| 5. | Tank | ||||||||||

| Nominal capacity |

dm³ |

300 |

400 |

600 |

800 |

1000 |

|||||

| Maximum capacity |

dm³ |

320 |

420 |

630 |

840 |

1050 |

|||||

| 6. | Capacity of pesticide diluent |

dm³ |

12 |

12 |

24 |

24 |

24 |

||||

| 7. | Tank for clean water to wash hands |

dm³ |

15 |

||||||||

| 8. | Control valve | ||||||||||

| Type |

– |

DL |

|||||||||

| Pressure gauge range |

bar |

0 – 40 |

|||||||||

| Number of connections on a receiver |

item |

4 |

|||||||||

| 9. | Fan attachment |

– |

traditional |

||||||||

| Number of spraying nozzles |

item |

12 |

|||||||||

| Number of units supplied separately |

item |

2 |

|||||||||

| Spraying nozzles |

– |

Double head with anti-leakage valve equipped with Lechler atomizers |

|||||||||

| Fan diameter |

mm |

825 |

|||||||||

| Fan efficiency |

m³/h |

16 000 – 48 000 |

|||||||||

| Fan rotations |

rpm |

2100 |

|||||||||

| Transfer of belt transmission |

– |

3,9 |

|||||||||

| 10. | Atomizers | ||||||||||

| – type |

– |

rotary |

|||||||||

| – color according to ISO |

– |

Yellow, green |

|||||||||

| – symbol |

– |

TR 80-02, TR 80-015 |

|||||||||

| 11. | Power demand |

kW |

35 |

35 |

50 |

50 |

50 |

||||