Opis

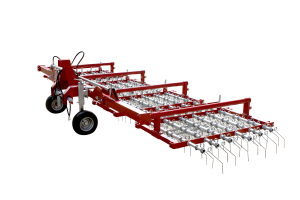

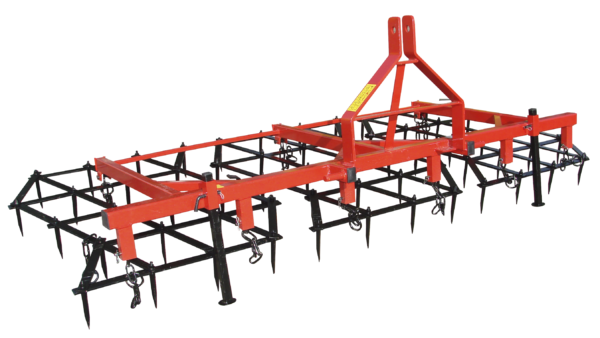

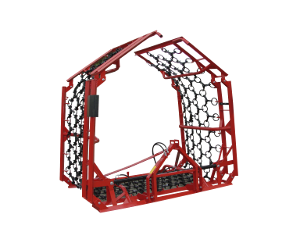

Weeder harrow is designed for harrowing grasslands – raking out sod and leveling molehills and cultivation of arable fields – destroying weeds and soil crust. Moreover, the harrow equipped with rigid spring fingers is designed for cultivation of fields after postharvest cultivation and harrowing low stubbles that is raking out crop residues and destroying weeds and self-seeding. Weeder harrow after being equipped with additional working elements, knife skid and a rear smooth roller, forms a tending set. The tending set, equipped with a skid, enables cutting sod and precise leveling molehills during cultivation of grassland whereas during cultivation of fields after skimming, enables leveling unevenness on the field surface. Rear smooth roller of the tending set is employed to cover grass seeds or seed aftercrop with a disc spreader. Aftercrop seeder can be suspended on the front three-point suspension system of the tractor. Manufactured series of types of a weeder harrow covers tools equipped with 2, 4 or 6 working units. 4- and 6-unit harrows are folded hydraulically for transportation. Regardless of the number of units, a harrow can be equipped with working units of width 1.5 m or 1.2 m, suspended swingingly on the frame, equipped with spring teeth of various characteristics and scale.

Technical specification of weeder harrow

| Lp. |

Specification |

Unit of measure |

Data |

||

|

1 |

2 |

3 |

4 |

5 |

6 |

| 1. | Machine symbol |

– |

P510 |

P510/1 / P510/2 |

P510/3 / P510/4 |

| 2. | Units number |

– |

2×1,5 |

4×1,2 / 4×1,5 |

6×1,2 / 6×1,5 |

| 3. | Working width |

m |

3 |

4,8 / 6 |

7,2 / 9 |

| 4. | Overall dimensions for a harrow with a roller | ||||

| – width |

mm |

3000 |

4840 / 6000 |

7240 / 9000 |

|

| – length |

mm |

2970 |

|||

| – transportation height |

mm |

1230 |

1710 / 1930 |

2940 / 3620 |

|

| 5. | Overall diamensions for a harrow | ||||

| – width |

mm |

2980 |

2550 / 2980 |

2550 / 2980 |

|

| – length |

mm |

2210 – 2300 |

|||

| – transportation height |

mm |

1230 |

1710 / 1930 |

2940 / 3620 |

|

| 6. | Working unit | ||||

| – teeth type |

– |

spring: Ø7 or Ø8 – double, Ø9 – single |

|||

| – working depth |

mm |

up to 50 |

|||

| – teeth diameter |

mm |

7 , 8 or 9 |

|||

| – teeth number in a row |

item |

6 |

|||

| – base of teeth rows |

mm |

250 |

|||

| – base of teeth Ø7 or Ø8 in a row |

mm |

150 |

|||

| – base of teeth Ø9 in a row |

mm |

300 |

|||

| – number of teeth Ø7 or Ø8 in a unit |

item |

1,5m-30 / 1,2m-24 |

|||

| – number of teeth Ø9 in a unit |

szt. |

1,5m-30 / 1,2m-24 |

|||

| – number of teeth Ø7 or Ø8 in a tool |

szt. |

3m – 60 |

4,8m -96 / 6m-120 |

7,2m-144 / 9m-180 |

|

| – number of teeth Ø9 in a tool |

szt. |

3m – 60 |

4,8m -96 / 6m-120 |

7,2m-144 / 9m-180 |

|

| 7. | Weight | ||||

| – harrow with teeth Ø7 or Ø8 |

kg |

3m – 270 |

4,8m – 535 / 6m – 640 |

7,2m – 760 / 9m – 895 |

|

| – harrow with teeth Ø9 |

kg |

3m – 265 |

4,8m – 520 / 6m – 620 |

7,2m – 740 / 9m – 865 |

|

| – harrow with teeth Ø7 or Ø8 with a roller and a skid |

kg |

3m – 420 |

4,8m – 780 / 6m – 925 |

7,2m – 1130 / 9m – 1360 |

|

| 8. | Power demand | ||||

| – for a weeder harrow |

KM |

3m – 30 |

4,8m – 48 / 6m – 60 |

7,2m – 72 / 9m – 90 |

|

| – for a harrow with a skid and a roller |

KM |

3m – 36 |

4,8m – 58 / 6m – 72 |

7,2m – 87 / 9m – 108 |

|

| 9. | Effective eficiency at speed 10 km/h |

ha/h |

3m – 3,0 |

4,8m – 4,8 / 6m – 6,0 |

7,2m – 7,2 / 9m – 9,0 |